Welcome to GEE ESS Engineering Works

GEE ESS's malleable, ell steel fabricated and forged conveying or elevating is required, all over the Indian subcontinent and to the different parts the world these are regularly supplied to the plants and to the onginal equipment manufacturers and as spares to various kind of machines along with the corresponding and other attachments.

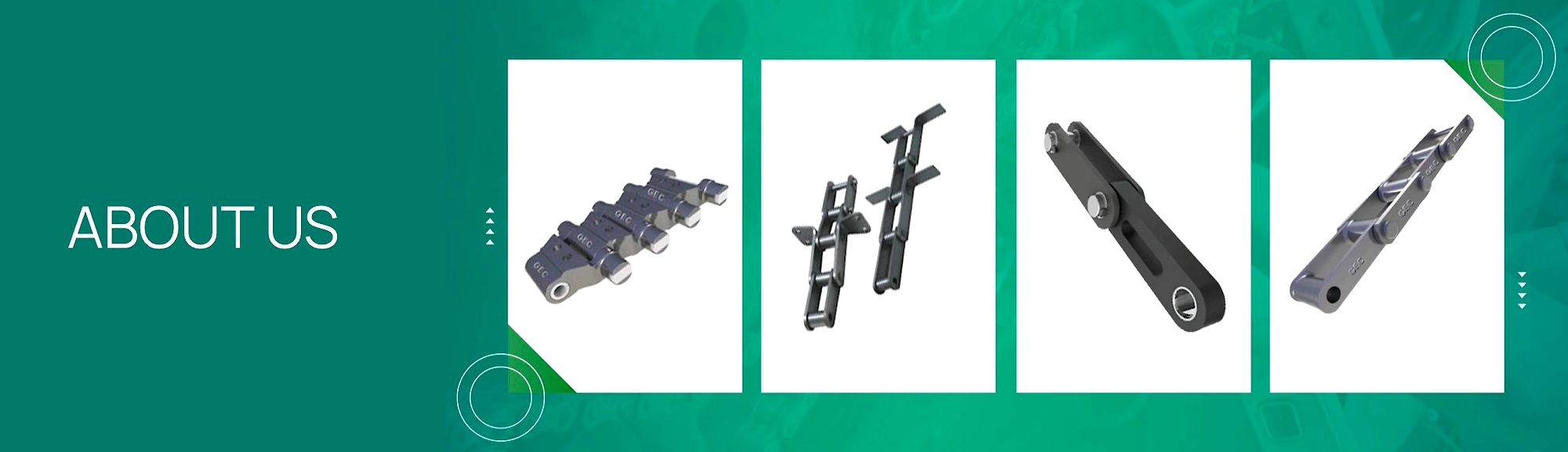

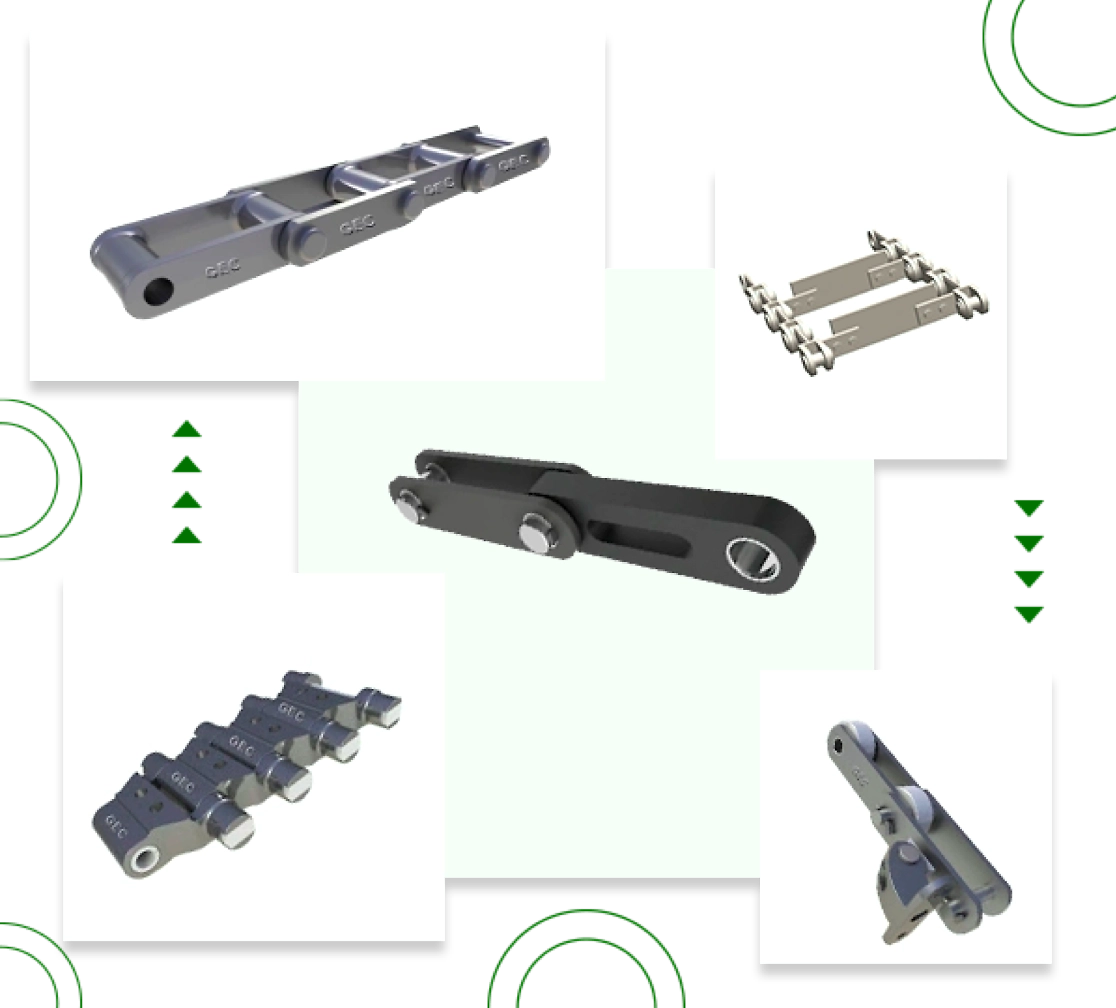

We are manufacturing e wide range of chains, from 2.5* pitch to 12' pitch & chains (long prich & heavy duty) for special applications. Our chains are well known for their strength ruggedness and durablity. We have achieved many distinctions in manufacturing and improving the quality of chains which used to wear out within the shortest period.

GEE EES has followed a tradition. A tradition of identifying with the technologist and engineer, his needs wants, upholding the cause, trying to find a solution to his each problem and applying the experience gained on the future supplies various types of chain are being manufactured under the progressive design and development along with the user engineers, manufacturing of all the chains is done in a technologically sound environment following the most productive techniques involving the precise metallurgical and manufacturing stages of controlled production making the chains to work under the most strenuous conditions.

We have the most modem machinery imbibing the latest technology. All side links are manufactured under the compound dies achieving the latest technology. All side links are manufactured under the compound dies achieving the accurate pitch. Intensive care is taken for the workmanship of the pins, bushes and rollers heat treatment is applied to achieve the required shear stresses, impact and wear resistance.

Areas of business

Covering our traditional sugar chain market of steel, mallable and stainless steel conveying chains; slates, scrapers, sprockets and buckets are also part of this division which caters for all types of chain and allied products supplied to the world's sugar industry. Besides, sugar industries our chains are used in paper, cement, ferilizer, mines bottling plants and other industries where chains are required for elevator, camer drawing and other purposes as per international and ISI specification.

Gee Ess manufactures conveyer chains & sprocket of the finest quality and is capable of producing up to 10000meters of special application chains every month.

Besides chains we are manufacturing cast steel sprockets, trash beans, crown pinions, coupling. fywheel, cane cutter knives, bearing housing rollers, fibrizer hammers and elevator buckets for sugar mills and other allied industries.

We undertake the fabrication and installation of complete conveyor on turkey basis.

Our Vision

We are proud to say that we being a part in the collaborative growth of our nation for mare than two dacades" our journey toward coaborative success has begun & we have long way to go. We see Gee Ess as one of the greasiest company representing India globally. We will be setting example of core engineering, fine technically, and moder mechanism and global recognitions.

Our Mission

We would like to serve aur clients with qualty conveyor chains & sprockets & other sugar mill spares at a very competitive price and fastest delivery.

Quality Control

• The organization has defined and established the management system in line with the ISO 9001:2000 Quality Management System. To provide the evidence of its commitment to the developed quality management system and implementation there of, the organization has established

• Quality Policy

• Quality objectives

• Commitment within the organization and with the customers Assurance of the resporsibility to satisfy our valuable with the technologist and engineer, his needs and wants, upholding the cause, trying to find a solution to his each problem and applying the experience gained on the future supplies. Vanous types of chains are being manufactured under the progressive design and development along with hands on experience with the user engineers. Manufacturing of all the chains is done in a technologically sound environment following the most productive and advanced production manufacturing stages of controlled production making the chains to work under the most strenuous.

• We have the most modem machinery imbibing the latest technology. All side links are manufactured under the compound dies achieving the accurate pitch. Intensive care is teken for the workmanship of pins, bushes and rollers. Heat treatment is applied to achieve the required shear stresses impact and wear resistance

• Camers for sugar mills on tumkey basis. Our complete steel camer is made with enough columns and supports to withstand higher capacity. These cames are available with ample carrier depth to feed/elevate the required capacity. Our camers are highly durable and designed to suit the customers needs and future up gradation in plant

• We are supplying to all the sugar factories in India and also to the plant manufactures like NHEC - pune, ISGEC New Delhi, Binny engineering organizations. We are exporting our products to West Indies, Vietnam, Rwanda, Uganda, Indonesia, Sri Lanka, Philippines.

Customers

We have our own in house metrological laboratory. Inspection of material is done at every stage right from incoming of raw material composition is tested on the spectrometer and breaking load test is performed on the universal testing machine. Every care is taken to control the quality and ensure the customer satisfaction.

Our concept

Quality cannot be inspected into a product; It has to be built into.*