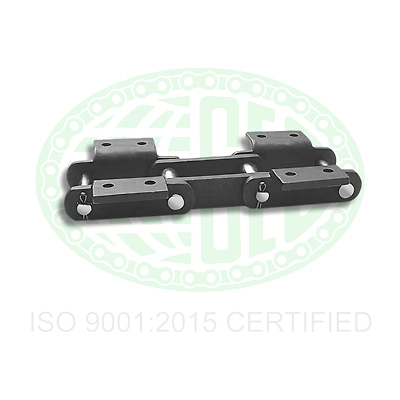

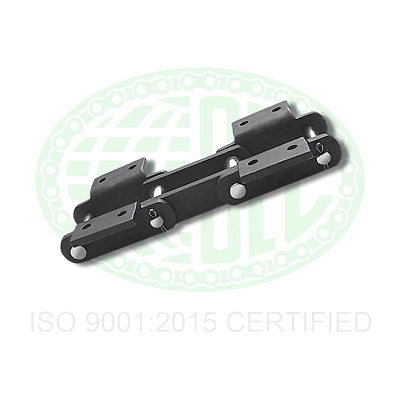

Bucket Elevator Chains

1.00

-

Product is not available

Country Of Origin : India

Bucket Elevator Chains are manufactured with high precision and special selection of materials, consider the operating loads and working conditions of chains. Pins and bushes are made from alloy steel for maximum wear life and toughness. Pins are through hardened and induction hardened to provide maximum wear resistance. The pins and bushes are also centerless ground to improve wear life and provide ideal fit between mating parts. All chain parts are designed to provide maximum fatigue life. Plates are through hardened for maximum strength without sacrificing necessary toughness. The full round design of pins and bushes eliminates stress risers in plate holes to maximise fatigue life. The plate hole size and finish are closely controlled to assure optimum press fit and fatigue life.

Key features

- Consistent overall tolerances make it ideal for conveying systems requiring precise alignment

- Maximum chain strength and resistance to wear are achieved by strict control of the material specification, and heat treatment processes to give maximum wear resistance to chain parts.

- Fatigue life is improved by maintaining precise fits and tolerances between the pins, bushes and side plates

- Chain and sprocket life are optimised by the rigid control of pitch accuracy, resulting in excellent gearing, lower friction and reduced wear.

- Bush and roller life are maximised by controlling the concentricity of these components and controlled heat treatment process

- Precise control of inner and outer plate clearances ensures effective lubricant penetration