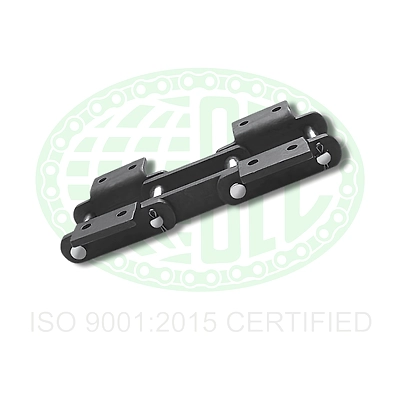

Bagasse Conveyor Chain

When high loads dictate a stronger chain all steel roller versions will meet the need. Slat type carriers with K2 attachments or Scraper type with AS2 attachments shown here, both with stainless Articulating parts will ensure trouble free inter carriers.

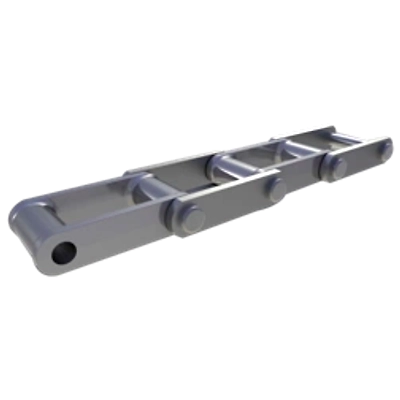

Forged Block Type Chain

These Chains are manufactured from selected quality steels with pins & Bushes of allay steel or stainless steel. We have successfully developed this chain which can stand for crushing 15 to 20 lacs Tan without any breakdown. We have supplied these chains to various mills directly and through the plant manufacturers and have received repeated orders.

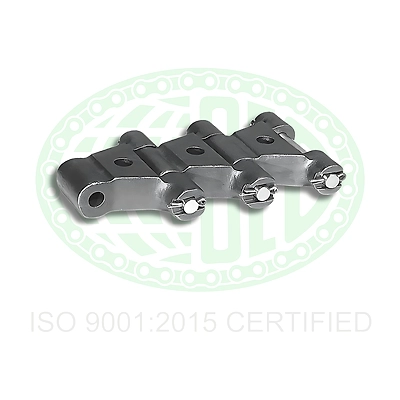

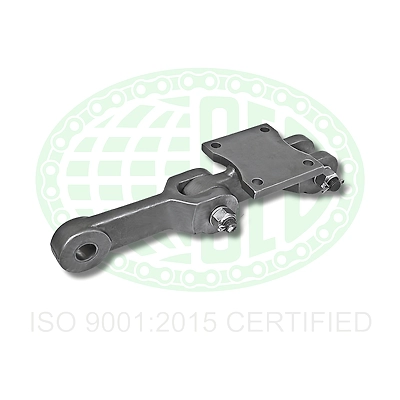

Intermediate Carrier Chain

These chains are usually manufactured from high quality alloy malleable iron as per international specifications. Inter carrier chain link are also available in forged steel (En8, En9). Pins and Bushes are of carbon steel and stainless steel, as suited to client's requirement.

Typical Material Handling Chains

Cement sand glass cullet flyash, lime stone ores, coal fertilizers, miscellanous powders flakes granules and pallets.

Bagasse Elevator & Conveyor Chains

Our Bagasse Carrier Chains are specially designed for sugar mills, ensuring efficient and continuous transportation of bagasse (sugarcane fiber waste) from crushing mills to boilers or storage areas. Made from high-strength alloy steel, these chains provide excellent wear resistance, high load capacity, and long service life, even in harsh environments.

Cane Feeder And Washing Table Chain

At GEE ESS, we offer high-performance Cane Feeder and Washing Table Chains designed specifically for the demanding operations of the sugar industry. These chains play a critical role in the initial stages of sugarcane processing—efficiently feeding and cleaning raw cane before it enters the crushing mills.

Slats

GEE ESS designs and manufactures robust and reliable Slat Conveyors for a wide range of industrial material handling applications. Built for strength and longevity, slat conveyors are ideal for transporting heavy, sharp, hot, or bulky materials that standard belt conveyors cannot handle effectively.

Reclaimer Chains

GEE ESS offers robust and high-performance Reclaimer Chains designed to handle the most demanding bulk material handling applications in industries such as mining, cement, power generation, and steel production. These chains are a critical component in reclaimer systems, responsible for efficiently moving bulk materials like coal, limestone, clinker, ores, and biomass from storage piles to processing systems.

Forged Link Block Type Chains

GEE ESS manufactures premium-quality Forged Link Block Type Chains designed for heavy-duty applications involving extreme loads, impact, and abrasion. These rugged chains are widely used in industries such as mining, cement, steel, biomass, and power generation, particularly in reclaimer systems, drag conveyors, and ash handling equipment.

Combination Chains

GEE ESS supplies durable and cost-effective Combination Chains, specially designed for light to medium-duty conveying and elevating applications. These chains are widely used in industries such as cement, mining, paper, grain handling, and agriculture where abrasion resistance and strength are required without the high cost of full alloy steel chains.

Apron Conveyor

GEE ESS offers heavy-duty Apron Conveyors engineered for reliable material handling in the most demanding industrial environments. These conveyors are designed to transport large, hot, abrasive, or heavy materials that standard belt conveyors cannot manage effectively. Ideal for industries such as mining, cement, steel, power generation, and foundries, apron conveyors ensure continuous and safe movement of bulk materials over long distances or through harsh conditions.

Apron conveyors consist of overlapping metal pans (aprons) mounted on heavy-duty chains, forming a rugged conveying surface that resists spillage and wear. Their robust construction makes them suitable for horizontal or inclined conveying of hot clinker, slag, coal, stone, or other coarse materials.

Block Link Chains

GEE ESS supplies robust and highly durable Block Link Chains designed for the toughest conveying and material handling applications. Known for their solid, compact construction, block link chains are ideally suited for operations involving high impact, heavy loads, and abrasive materials—common in industries such as cement, mining, steel, power generation, and bulk material handling.

Cane Carrier Roller Chains

Our Cane Carrier Chains are specially designed for sugar mills and processing plants, ensuring smooth and efficient cane transportation. Manufactured from high-strength alloy steel, these chains offer exceptional durability, wear resistance, and load-bearing capacity, making them ideal for heavy-duty applications.

Bucket Elevator Chains

At GEE ESS, we specialize in providing premium-quality Bucket Elevator Chains designed for efficient and reliable vertical material handling in a wide range of industries. Manufactured to meet the highest standards of strength and durability, our bucket elevator chains are built to handle everything from grain and fertilizers to heavy aggregates and industrial materials.

Intermediate Carrier Chains

Our Intermediate Carrier Roller Chains are designed for continuous material handling in sugar mills, cement plants, and conveyor systems. These chains provide high wear resistance, smooth operation, and extended service life, ensuring efficient material transfer with minimal downtime.

Intermediate Carrier Roller Chains

Our Inter Carrier Chains are designed for continuous and heavy-duty material transport, commonly used in sugar mills, cement plants, and industrial conveyor systems. Available in both forged and malleable designs, these chains offer superior strength, flexibility, and durability, ensuring seamless operation with minimal maintenance.

Heavy Duty Welded Steel Drag Chain

Boiler Stoker Chains – Engineered for High-Temperature Performance!

Our Boiler Stoker Chains are designed to withstand extreme heat and high-load conditions in industrial boiler systems, power plants, and furnaces. These chains ensure efficient fuel feeding, smooth operation, and long service life even in high-temperature environments.

BLOCK FORGED CHAINS

Our Block Forged Chains are designed for high-load and impact-resistant applications, making them ideal for use in conveyors, material handling, sugar mills, and heavy-duty industrial systems. Manufactured from precision-forged alloy steel, these chains provide superior strength, wear resistance, and long service life in demanding environments.

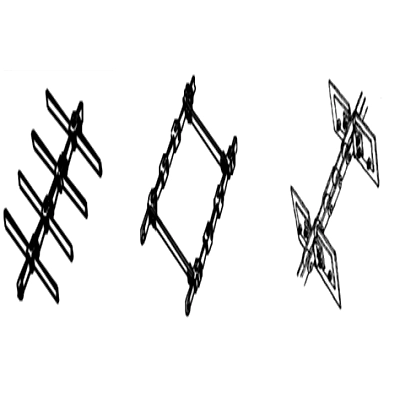

Sugar Elevator Chains

Our Sugar Elevator Chains are engineered for smooth and efficient lifting of sugar and other materials in sugar mills. These chains are built for high durability, wear resistance, and long service life, ensuring uninterrupted operation with minimal maintenance. Sugar Elevators, A Small Cross Section Is Shown Here.

Sprockets

At GEE ESS, we offer a wide range of premium-quality chain sprockets designed for maximum performance, reliability, and efficiency in power transmission applications. Manufactured from high-grade materials and engineered to precise tolerances, our sprockets ensure smooth, wear-resistant operation in even the most demanding industrial environments.