Bucket Elevator Chains

At GEE ESS, we specialize in providing premium-quality Bucket Elevator Chains designed for efficient and reliable vertical material handling in a wide range of industries. Manufactured to meet the highest standards of strength and durability, our bucket elevator chains are built to handle everything from grain and fertilizers to heavy aggregates and industrial materials.

Reclaimer Chains

GEE ESS offers robust and high-performance Reclaimer Chains designed to handle the most demanding bulk material handling applications in industries such as mining, cement, power generation, and steel production. These chains are a critical component in reclaimer systems, responsible for efficiently moving bulk materials like coal, limestone, clinker, ores, and biomass from storage piles to processing systems.

Apron Conveyor

GEE ESS offers heavy-duty Apron Conveyors engineered for reliable material handling in the most demanding industrial environments. These conveyors are designed to transport large, hot, abrasive, or heavy materials that standard belt conveyors cannot manage effectively. Ideal for industries such as mining, cement, steel, power generation, and foundries, apron conveyors ensure continuous and safe movement of bulk materials over long distances or through harsh conditions.

Apron conveyors consist of overlapping metal pans (aprons) mounted on heavy-duty chains, forming a rugged conveying surface that resists spillage and wear. Their robust construction makes them suitable for horizontal or inclined conveying of hot clinker, slag, coal, stone, or other coarse materials.

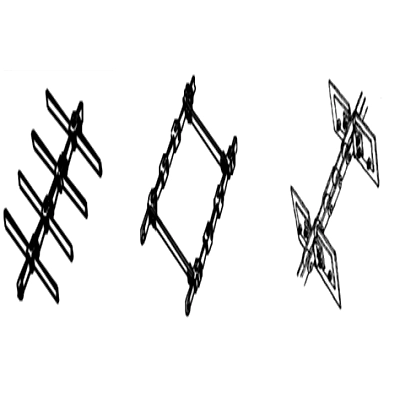

Typical Material Handling Chains

Cement sand glass cullet flyash, lime stone ores, coal fertilizers, miscellanous powders flakes granules and pallets.

Heavy Duty Welded Steel Drag Chain

Boiler Stoker Chains – Engineered for High-Temperature Performance!

Our Boiler Stoker Chains are designed to withstand extreme heat and high-load conditions in industrial boiler systems, power plants, and furnaces. These chains ensure efficient fuel feeding, smooth operation, and long service life even in high-temperature environments.

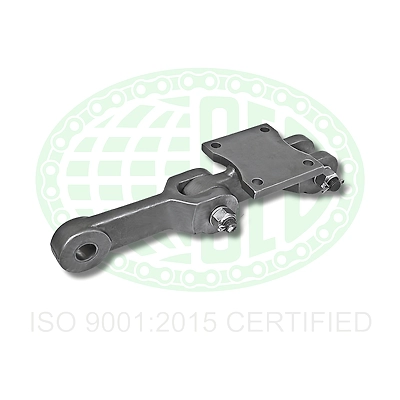

BLOCK FORGED CHAINS

Our Block Forged Chains are designed for high-load and impact-resistant applications, making them ideal for use in conveyors, material handling, sugar mills, and heavy-duty industrial systems. Manufactured from precision-forged alloy steel, these chains provide superior strength, wear resistance, and long service life in demanding environments.